Efficiency and resilience in electronics manufacturing with M4ESTRO - An interview with Intellimech and FAE

The manufacturing industry is under mounting pressure. From supply chain disruptions triggered by global uncertainty to the demand for quick process adaptability and advanced digital solutions, critical challenges are here. In response to these needs, M4ESTRO seeks to create a cutting-edge, certified platform for the provision and coordination of Manufacturing as a Service (MaaS) services.

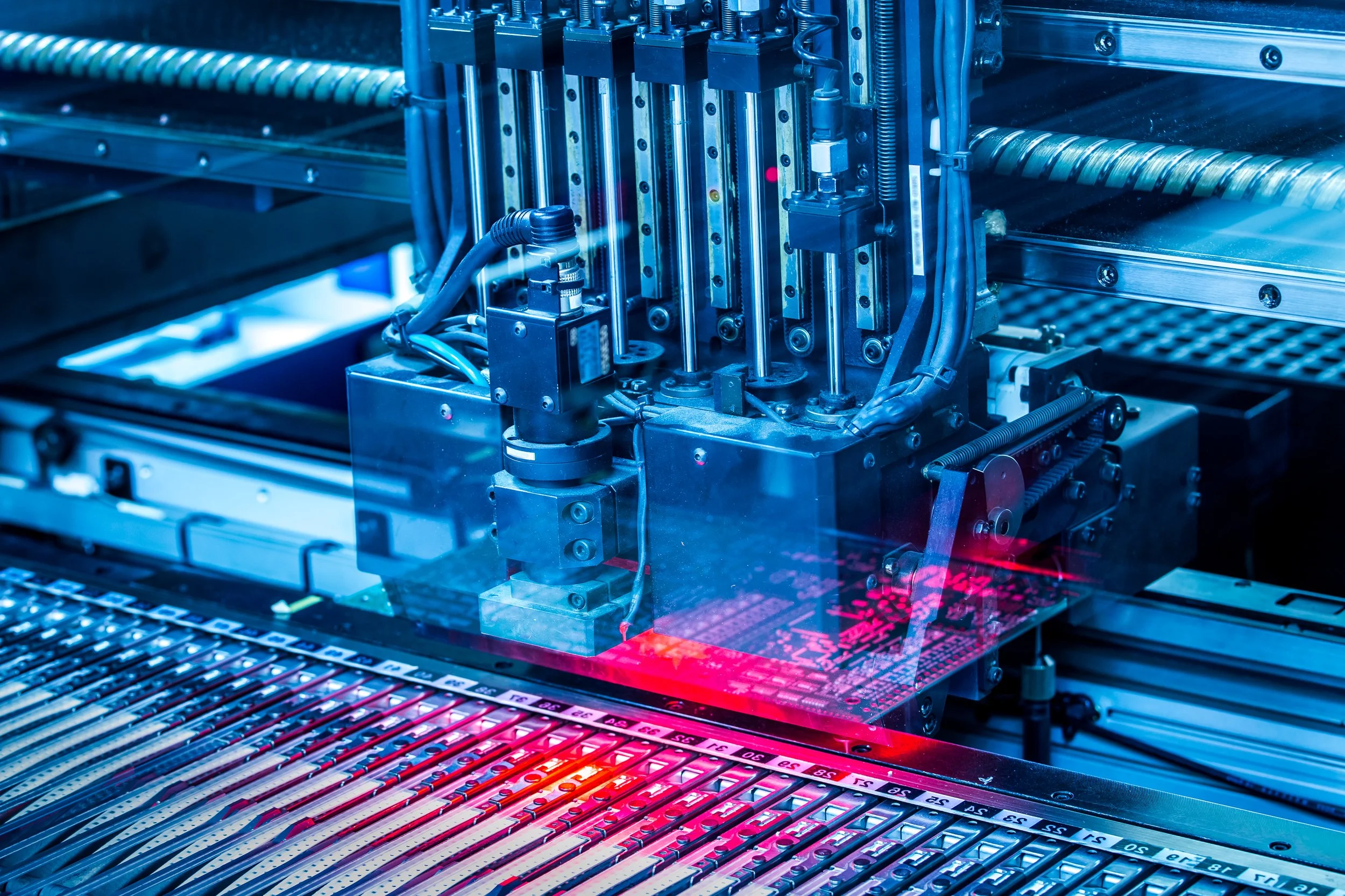

Within M4ESTRO, Intellimech and FAE Technology work on the validation of technologies, related to supply chain management and advanced electronics manufacturing. The two organizations collaborate to integrate the M4ESTRO framework into the MyFASTPCBA platform which will allow them to increase the efficiency and resilience of FAE’s service offerings.

To understand how this vision is taking shape, we caught up with Davide Cesani, researcher at Intellimech, and Giovanna Gozio and Alessandro Racheli, project managers at FAE Technology, to learn more about their work in M4ESTRO.

“In today’s globalized context, managing a manufacturing supply chain involves many complex challenges. Economic uncertainty and geopolitical tensions create instability, making it difficult to plan and maintain efficient and resilient production. Furthermore, increasing demand for customization and quick turnaround times clash with the growing pressures of sustainability and environmental concerns.” explains Cesani at the beginning of our discussion.

He also added “M4ESTRO offers an innovative response by providing a comprehensive digital platform based on the Manufacturing-as-a-Service (MaaS) model. It enhances transparency, flexibility, and collaboration throughout the supply chain while promoting a human-centered, sustainable, and efficient planning approach.”

In our conversation, Cesani put his finger on the critical issue of Artificial Intelligence in data and crisis management. He pointed out that

“AI methods are playing an increasingly central role in supply chain planning, significantly improving both its effectiveness and operational robustness. Thanks to their ability to process and analyze large volumes of data in real-time, these tools can predict potential mismatches between supply and demand and suggest timely corrective actions. This includes mitigating supplier delivery delays, sudden changes in demand, or disruptions in logistics networks.”

Giovanna Gozio and Alessandro Racheli broadened our view of FAE Technology’s role:

“FAE participates in M4ESTRO as a pilot to validate the technologies developed within the project. Currently, the company offers prototyping services through the MyFASTPCBA platform, which supports custom quotations and order management, while also allowing real-time evaluation of component availability. FAE aims to optimize its prototyping line by adopting the M4ESTRO solutions. Our special focus is on resilience and how to better handle the supply chain instability that affects the electronics sector.”

They also touched on the topic of digital technologies under development:

“We’re experimenting with data analysis and AI to assess risks, especially those related to the supply chain, and to propose more reliable design alternatives, even using natural language interfaces. We're also using optimization algorithms for dynamic scheduling and delay management, and introducing tools such as the Digital Product Passport to enable circular strategies for reuse and refurbishment, aiming to reduce costs, lead times, and environmental impact.”

When the conversation came to what the future holds for Manufacturing-as-a-Service in the electronics sector, they added “The electronics industry is particularly vulnerable to supply chain instability and must evolve to address the obstacles of an ever-changing landscape. Among the key challenges MaaS must tackle is the implementation of circular services aligned with industry trends supporting the full lifecycle of electronic boards, including end-of-life collection and recycling of electronic equipment.”

This interview was originally published in the Italian SmartNews magazine.